What's the deal with using raw, thermized, or pasteurized milk for cheesemaking?

All cheesemaking starts with milk, most commonly from cows, goats, and sheep. Healthy, grass-fed animals of any breed are most likely to produce equally healthy milk that creates the most delicious, flavor-packed cheeses. Early in the cheesemaking process, the cheesemaker decides whether to work with raw, unheated milk, filled with naturally occurring bacteria and enzymes, or with milk heated to kill off both the good and bad bacteria as well as any enzymes. This decision is often influenced by government regulation which may mandate the milk treatment for a particular cheese (e.g. the AOC and DOP regulations) or may broadly limit the use of unpasteurized milk in cheese production.

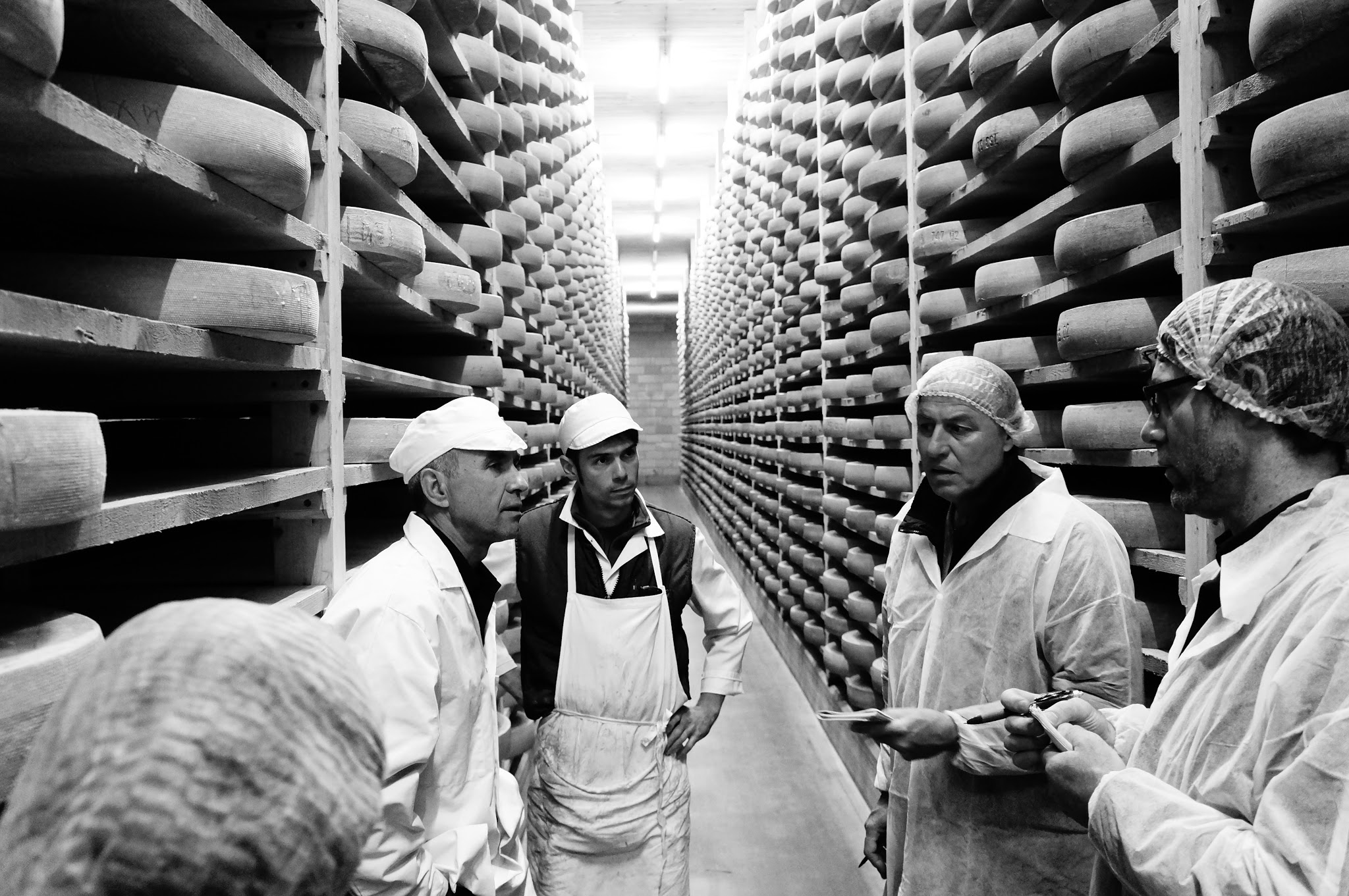

A visit to Fromagerie Marcel Petite: Affineur de Comté

A visit to Fromagerie Marcel Petite: Affineur de Comté

The question of raw vs. pasteurized milk in cheesemaking is a hotly debated topic with very strong proponents on each side. To truly understand the complete discussion, we have to start by defining a few terms.

- Raw milk has not been heated beyond 40 degrees Celsius (104 degrees Fahrenheit) and has not undergone any treatment that has an equivalent effect.

- Unpasteurized milk refers to all milk that is not, by definition, pasteurized. This is important for legal and regulatory purposes.

- Thermized milk (sometimes incorrectly referred to as thermalized milk) has been heated to a temperature between 57 degrees and 68 degrees Celsius (135 to 154.4 degrees Fahrenheit) for at least 15 seconds. This process kills some, but not all of the natural bacteria and enzymes in milk, keeping more of the natural flavors in the milk than pasteurization. This milk is not technically raw, but is technically unpasteurized.

- Pasteurized milk has undergone the process of heating every particle of milk, in properly designed and operated equipment, to a specific temperature for a set amount of time. Most commonly, pasteurization is done in one of two ways. The faster, more economical method heats the milk to 72 degrees Celsius (161 degrees Fahrenheit) and maintains that temperature for 15 seconds. An alternative method of pasteurization, also known as 'vat' or batch pasteurization, heats the milk to 63 degrees Celsius (145 degrees Fahrenheit) and holds it there for 30 minutes. This slower method takes more time, is more expensive, and is often the preferred method of pasteurization for cheesemaking as it maintains some flavor elements of the milk.

- Ultra High Temperature Milk (UHT) has been flash heated at at 138 degrees Celsius (280 degrees Fahrenheit) for at least two seconds before or after packaging. This milk has an extended shelf life under refrigerated conditions, but is not well suited to cheesemaking.

Why Pasteurized Milk?

Pasteurization is designed to kill off all bacteria and enzymes in the milk, good and bad, to provide something of a clean slate for the cheesemaker. Eliminating these enzymes introduces more control to the cheesemaking process, resulting in a raw material that is more predictable throughout the process of cheesemaking, but that requires the addition of more outside cultures to replace lost microflora. The resulting wheels of cheese tend to have a more consistent taste, texture and moisture content.

In both the United States and Europe, cheeses are made with pasteurized, thermized, and raw milk, but the production and sale of raw milk cheese is heavily regulated. Since 1950, all cheese sold in the United States must be made with pasteurized milk, or, if made with raw milk, aged at least 60 days to allow potentially present pathogens such as Listeria, E. coli, or salmonella to die off.* The idea behind this approach suggests that pathogens die off during this aging period, and the increasingly dry and acidic environment of the aging cheese should prevent any environmental pathogens from taking hold.

The European Union has its own set of strict regulations (40 + pages!) for cheesemaking and milk handling to guarantee safety.

All of these regulations are geared to prevent listeriosis, an uncommon, but often fatal disease linked with exposure to listeria monocytogenes. This listeria lives in soil, decaying vegetation, and water and is a hardy bacterium that can grow under refrigeration and can persist for months. While listeria can not survive pasteurization, if an environment is not properly sanitized, the bacteria can be introduced into a cheese after pasteurization takes place. For this reason, whether the milk is pasteurized or not, it is essential that any cheese is made and stored in a clean environment.

Why Raw Milk?

While pasteurized milk proponents will emphasize the value of safe food, the alternate view of the raw milk proponents stress that milk in its natural state is filled with important amino acids, probiotics, and the necessary colloidal minerals and enzymes that allow our bodies to absorb and utilize the natural sugars and fats present in raw milk. These proponents further suggest that raw milk rich with microbes may have an anti-pathogenic effect in which the good bacteria outcompete the bad.

Cheese Safety and Quality

Regardless of whether a cheese is made using pasteurized or unpasteurized milk, both sides agree it is critical that the producers, agers, and retailers observe the highest levels of food-safety in their operations to ensure a clean, high-quality product that tastes delicious.

Formaggio Kitchen has been working with both unpasteurized and pasteurized cheeses for over 35 years and we are strong supporters of well-crafted raw milk cheese made domestically and beyond. In our experience, it is absolutely possible to make delicious cheese from pasteurized milk, and we carry a large variety of exceptional cheeses of this kind including Colston Bassett Stilton and Cabot Clothbound Cheddar.

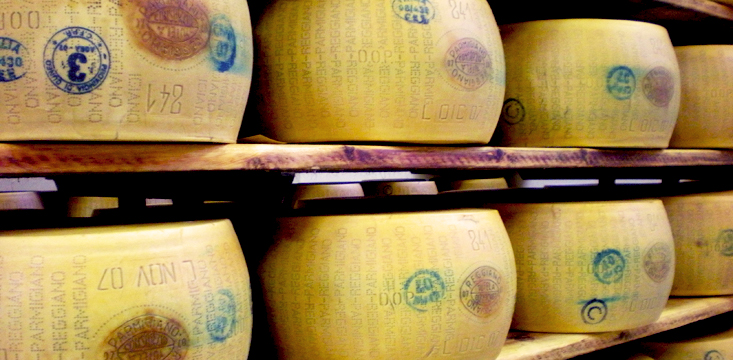

Still, there is something exquisite about an artfully-crafted, raw milk cheese in which you can find the aromatic, textural and flavor complexity particular to the region and producer - a unique and delicious taste of terroir, or taste of place, that would be wiped out if pasteurized milk had been used. This opinion is reflected in the decision by various European countries to codify the importance of using raw milk in some of the most famous cheeses in the world. Parmigiano Reggiano, Swiss Gruyère, and French Comté are examples that will always be made in the traditional method using raw milk - it's the law.

Aging Raw Milk Parmigiano Reggiano

As food lovers and responsible food purveyors, we want to have the highest quality, safest cheeses to enjoy and sell. We will continue to support artisan producers around the world producing exceptional raw milk cheeses so that the characteristics so unique to raw milk cheeses can be preserved and appreciated for years to come.

* The FDA is currently reviewing regulations for cheeses made using unpasteurized milk in an ongoing process to balance science-based regulations to protect public health while helping preserve and promote healthful and safe raw milk cheese production.

Sources:

- Cheese Primer by Steven Jenkins

- FDA Guidance and Regulation: Pasteurized Milk Ordinance

- European Union: Health Rules for Production and Market Placement of Milk Products

- Mastering Cheese by Max McCalman and David Gibbons

- Slow Foods: European Law on Raw-Milk Cheese

- Old Ways Cheese Coalition Report - Hot Topic: Raw Milk Cheese

Author - Beth Wittenstein is a cheesemonger at Formaggio South End and Online Media Manager for Formaggio Kitchen Cambridge. When she isn’t taking photos of cheese, you can find her making intricate confections in her kitchen.